With the rapid development of science and technology, new quality productivity has become a powerful engine to promote economic and social development. Wave Group's Corelight Optoelectronics has followed the pace of the times and launched a brand new laser welding robot, which has injected a powerful impetus to the empowerment of new quality productivity with its high efficiency, stability and accuracy.

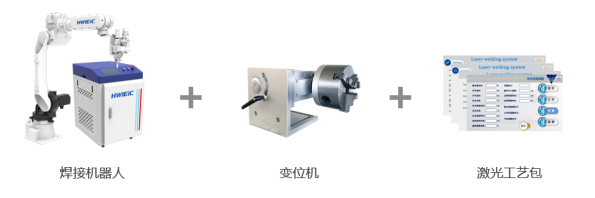

The laser welding robot, as an outstanding representative of the new quality productivity, integrates advanced laser technology, robotic arm technology and intelligent control system, realizing the comprehensive automation and intelligence of the welding process. It is not only able to adapt to the production needs of different workpieces and carry out 360° angle welding to ensure that the quality of weld seams is significantly improved, but also able to work stably for 24 hours without interruption, which greatly improves the efficiency and productivity of welding work.

The HJR series of welding robots introduced by Coretronic has become a powerful assistant in the field of industrial manufacturing with its remarkable advantages of flexible adaptability, efficient continuous work, high precision and stability, and reduced labor costs. Whether it is automobile manufacturing, aerospace and other heavy industry, or electronics, communications and other light industry, HJR series can play a good job, help enterprises to realize the transformation and upgrading, enhance competitiveness.

Taking a water meter assembly plant in Shandong as an example, the laser welding robot solution customized by CorePhotonics has successfully solved the problems of unstable weld quality, difficult operation and high safety risk that existed in the traditional manual welding method. Through the implementation of this solution, the welding efficiency of this water plant has been significantly improved, and the quality of weld seams has become more stable. Employees can master the robot's operating skills with simple training, reducing operating difficulties and safety risks.

The wide application of laser welding robots not only promotes the upgrading of the intelligent manufacturing industry, but also provides strong support for the development of new quality productivity. With its high efficiency, precision and stability, it has revolutionized the production process, improved production efficiency, reduced production costs and created greater value for enterprises.

In the future, with the continuous progress of science and technology and expanding market demand, laser welding robots will be widely used in more fields. Wave Group Core Optoelectronics will continue to plough into the field of laser machine applications, continue to innovate and breakthrough, launch more advanced products in line with the requirements of the development of the new quality of productivity, and contribute more to the promotion of high-quality economic and social development.

Source: OFweek Laser

Tel. wechat: +86 17665360831(Mr Wu)

Whatsapp: +86 15820436325(Mr. Wu)

Tel. wechat Facebook: +86 13924619027(Windy)

Add: 510 Kunhong building, No. 38 Xinhe Avenue, Xinqiao Street, Baoan District, Shenzhen City, China